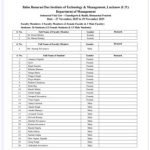

Industrial Visit to Baddi, Himachal Pradesh

Brief Description:

The Department of Management, BBDITM Lucknow organized a three-day Industrial Visit for First Year MBA students to Baddi, Himachal Pradesh from 27th to 29th November 2025. The visit aimed to provide students with hands-on exposure to real-time industrial operations, production systems, quality management, supply chain practices, technological innovations, and HR processes across three major manufacturing units — Suvidha Home Appliances (Elin Appliances Pvt. Ltd.), Indo Farm Equipment Ltd., and Steelbird Helmets. The department expresses its sincere gratitude to the Prof. (Dr.) Anurag Tiwari,Director, BBDITM for his valuable support and guidance in organizing the industrial visit, and toProf. (Dr.) Divya Gangwar, Head, Department Of Management, BBDITM forher effective coordination and constant efforts in making the event successful. The visit successfully bridged theoretical concepts with practical industry applications, enhancing students’ understanding of business processes, production systems, market dynamics, and modern industrial practices.

Objectives of the Industrial Visit

- To provide students with practical exposure to industrial operations and workflow.

- To understand business strategies, production systems, and current market trends.

- To gain insights into supply chain and inventory management practices.

- To interact with industry professionals and explore real career pathways.

- To bridge the gap between classroom concepts and real-world business functioning.

Program Date:

27th November 2025 – 29th November 2025

Venue:

Baddi Industrial Area, Himachal Pradesh

Target Group:

MBA First Year Students (1st.&3rd. Semester)

Faculty Coordinators:

- Preeti Mishra, Professor, Department of Management

- Meetu Pandey,Associate Professor, Department of Management

- Anurag Srivastava,Assistant Professor, Department of Management

Attendance:

Total Students: 26

Faculty Members: 3

Summary of the Event:

Day 1 – 27th November 2025

Visit to Suvidha Home Appliances (Elin Appliances Pvt. Ltd.) – Mixer Grinder Manufacturing Unit

Students explored large-scale manufacturing processes, including fabrication, assembly, quality testing, packaging, and dispatch operations. The session highlighted how modern technology and semi-automated machinery enhance productivity and maintain quality. The visit bridges theoretical knowledge with practical application, showing students how raw materials are processed, products are assembled on semi-automated lines, and how quality control, packaging, and dispatch are managed. They gain insight into market demands, inventory control, and the implementation of modern manufacturing practices.

Major Learnings by Students

- Production & Assembly: Observed raw material storage, motor winding, assembly lines, and testing operations.

- Quality Assurance: Understood multi-stage inspections, durability tests, and safety compliance.

- Inventory & Supply Chain: Exposure to ERP-based inventory systems and dispatch processes.

- Logistics & Packaging: Insight into eco-friendly packaging and shipment processes.

- Market Orientation: Learned how production planning aligns with customer demand.

- Use of Technology: Observed precision machines and automation in manufacturing.

Day 2 – 28th November 2025

Visit to Indo Farm Equipment Ltd.

Students learned about tractor and farm equipment manufacturing, assembly line operations, and production management techniques.The manufacturing processes of tractors and farm equipment, encompassing production management, assembly line operations, plant and inventory management, along with the key factors affecting product quality and market demand.

Major Learnings by Students

- Manufacturing & Production: Detailed observation of tractor assembly and testing.

- Production & Inventory Management: Understood stock control systems and capacity planning.

- Market Demand & Strategy: Learned how production matches market requirements.

- Industry-Academia Link: Strong connection between classroom theory and industry practice.

Industrial Visit to Steelbird Helmets

This visit offered deep insights into the helmet manufacturing process, design innovation, and strict quality standards. Industrial visit to the Steelbird Helmets factory provided an immersive journey into the production of high-quality helmets. Renowned as a leading brand in the industry, Steelbird Helmets has garnered applause for its unwavering commitment to safety, innovation, and superior craftsmanship. During this visit, the HR manager, Mr Vishal Tyagi graciously guided students through the intricate manufacturing processes of the company. With expertise and enthusiasm, he elucidated the various stages involved in crafting helmets of exceptional quality. In addition to manufacturing, the HR manager also shed light on the assembly and painting processes within the facility. Students gained valuable insights into the sophisticated techniques employed to ensure durability, aesthetics, and compliance with regulatory standards.

Major Learnings by Students

- Production Floor Tour: Students saw moulding, cutting, assembly, painting, and finishing operations.

- Design & Innovation: Exposure to advanced materials, ergonomic designs, and safety technologies.

- Quality Assurance: Understood rigorous testing methods ensuring maximum safety compliance.

- Safety Education: Awareness initiatives on road safety and helmet usage.

- Interactive Sessions: Discussions on market trends, safety standards, and career opportunities.

Overall Outcome

The industrial visit proved highly enriching. Students and faculty appreciated the exposure to real industrial settings, modern technologies, and management practices. The visit enhanced students’ practical knowledge, boosted industry readiness, and strengthened their understanding of management concepts.